In the maintenance and management of modern transportation infrastructure, defect detection on highways is always a critical step in ensuring driving safety and road lifespan. Recently, during a radar detection project on a highway, we fully demonstrated the efficiency and precision of 3D array ground penetrating radar system.

Project Background

Radar detection was conducted on the highway segment K1229 + 300 - K1228 + 900. This highway segment has heavy traffic and complex road conditions. Traditional detection methods are not only time-consuming and labor-intensive but also difficult to detect subsurface road defects accurately. Our 3D array ground penetrating radar system successfully completed an non-destructive, blind detection tasks on this segment at high driving speed of 80km/h.

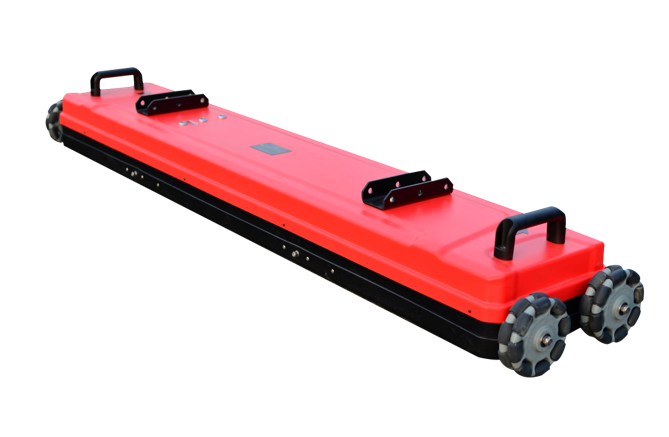

LGPR 3D-1200AT14 Three-dimensional Array Radar System

Technology Application

Technical Principle

The 3D array ground penetrating radar scans the highway surface at high driving speed, using multi-angle, high-resolution radar signals for comprehensive detection of highway pavement defects.

Technical Advantages

• Non-destructive detection at high driving speed (80 km/h), avoiding the impact on traffic by traditional methods

• Multi-dimensional data processing for precise location of defects positions

• Clear radar images that intuitively showing defect types and depths

Detection Process

Detection Conditions

• Equipment Status: Normal operating condition

• Driving Speed: 80 km/h

• Scanning Range: 200m×100m

Data Processing and Analysis

• Use advanced data processing algorithms for quick radar signal analysis

• Automatically generate radar images that clearly reflect defect characteristics

Precise Verification and Efficient Operation

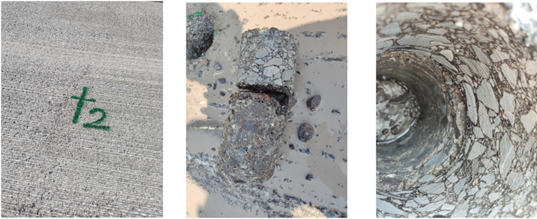

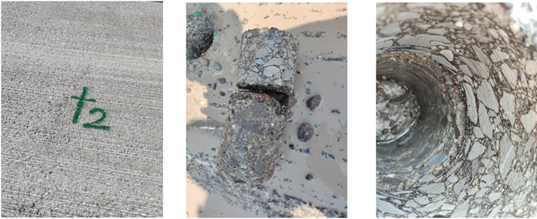

After marking defect positions, the on-site core sampling verification was immediately conducted. Total 4 core samples were taken for the verification, with encouraging results: all core samples accurately located defect positions, fully consistent with radar images. Below are some verification results:

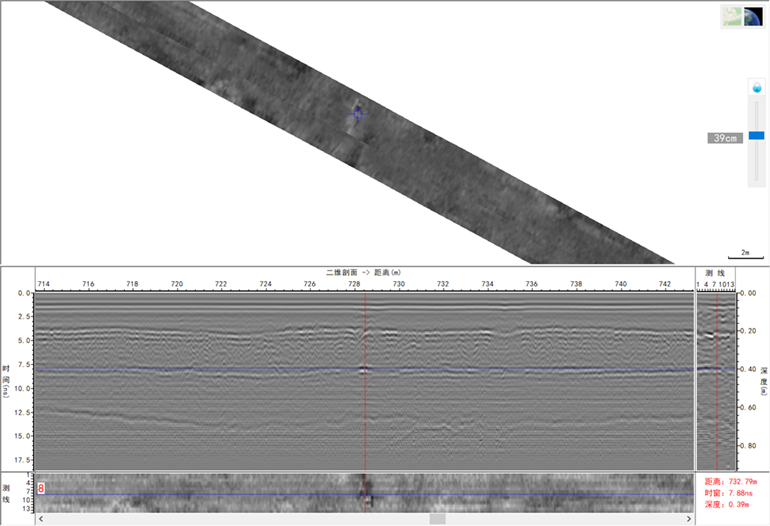

• Defect 1: Cracks in the upper base layer, and fragmentation at the interface between the upper and lower base layers (depth 0.18-0.40m). On-site coring verification showed obvious cracks after milling two layers of the pavement surface, with reflective cracks in the upper base layer, poor adhesion between the surface layer and base layer, and looseness and fragmentation between the upper and lower base layers.

• Defect 2: Looseness at the interface between the surface layer and upper base layer, and fragmentation at the interface between the upper and lower base layers (depth 0.20-0.40m). The radar image accurately reflected this, and on-site coring verification found looseness and fragmentation in the upper base layer after milling one layer of the pavement surface, with poor adhesion between the upper and lower base layers.

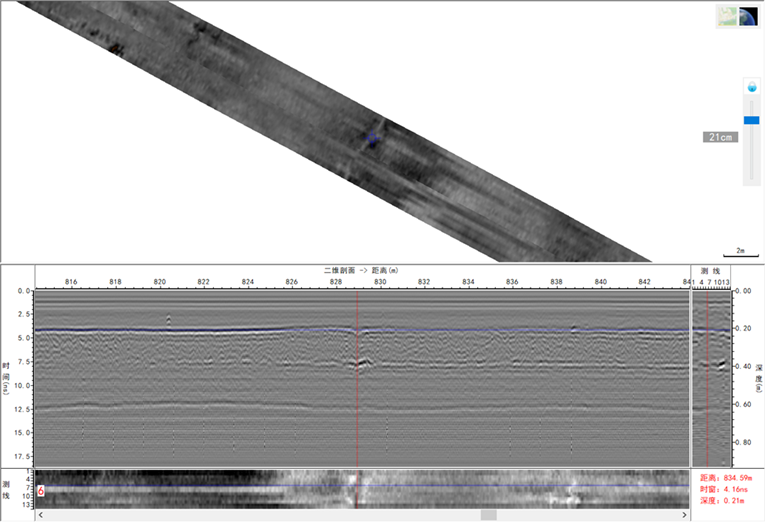

• Defect 3: Looseness and fragmentation in the upper base layer, with poor adhesion between the upper and lower base layers. The radar image showed the defect position, and on-site coring verifies the radar image was accurate.

• Defect 4: Looseness and fragmentation in the upper base layer. Gravel were observed in radar image. It was consistent with on-site coring verification results.

Radar Image

On-site Core Sampling Result

Radar Image

On-site Core Sampling Result

On-site Core Sampling Result

Conclusion and Outlook

This test fully demonstrates the efficiency and accuracy of 3D array ground-penetrating radar technology in detecting highway defects. Its technical advantages lie not only in improved detection efficiency but also in the precise location of actual defects. In the future, 3D array g

round-penetrating radar will unlock its potential in more fields, providing better and more reliable solutions for the maintenance and management of transportation infrastructure.